Service

Component Testing Center

Fully Serviced Test Center

Manufacturers typically do not provide support for failure analysis services if the source of material is not traceable. So where do you go for help? If you ask a supplier to provide a failure analysis, can you be sure that they will spend more time and money to meet your needs, or would they prefer to provide a report in their own favor?

NAITANG TEST is supported by proud professional engineers, and can use experimental analysis equipment at full discretion. The ability to discern beyond the general EOS failure can detect the real failure mode and failure principle.

Our Service

“ Buyers need to keep in mind that you need more than just chip ceramic capacitors, you need safety. Naitang Electronics ensures that the MLCC you purchase will operate according to the established requirements. ”

There are so many types and brands of MLCC products, from Class I ceramic materials and Class II ceramic materials, different withstand voltage values, models, to end-use scenarios. As industrial rice is used in new developments every day, different products require different angles to measure and identify their performance.

Our engineer used to be an electronic front-line technician, and has been engaged in the production, sales, and terminal use of passive components for many years. At present, it is an autocratic NAITANG TEST Company. At the end of 2021, he will be an engineer of Naitang Laboratory. He has more than 15 years of experience in the passive components industry. , is one of the witnesses of China's postmodern passive parts industry chain from raw materials to different terminal scenarios! Integrating various standard methods, testing equipment, detailed manufacturer specifications and a lot of industry experience, we have developed solutions that meet the current market to solve the various problems you encounter.

Label Verification

"Inspection Instructions"

1. The inspection of the label is based on the comparison and analysis of the label photo provided by the customer, the original label, the official website information, etc., from the font, format, number of fields, anti-counterfeiting point information, material, reflectivity, two-dimensional code and barcode in the label. information, etc. for comparison and verification;

2. The inspection conclusion is for reference only, and the actual product shall prevail. If you need to confirm whether the product is original, you can provide samples for appearance inspection or grinding disc comparison verification;

3. The standard inspection service is voluntary, and the customer bears the risk. Naitang Electronics will not be responsible for any consequences or legal responsibility for this.

External visual lnspection

Description:Visual testing refers to confirming the quantity of MLCC received, inner packaging, humidity indication, desiccant requirements and proper outer packaging. Secondly, the appearance inspection of a single MLCC mainly includes: the typing of the tray, the year, the country of origin, whether it has been re-coated, the state of the MLCC, whether there are unknown traces, residues, and the location of the manufacturer's logo.

Contents Of Appearance Inspection:

1. The contents of the package inspection include: scratches, smudges, damage, underfill, spillage, etc.

2. The content of printing detection includes: typo, offset, missing printing, multi-printing, blur, skew, displacement, hyphenation, double-layer printing, no font and so on.

3. Consistency of the empty tape of the material tape and the color of the adhesive tape, the direction of the tape winding, the concentricity of the material tape and the pull tape after bonding, the position of the slot of the material tape, the material and color of the material tray, the Model number, direction, depth, size, etc. of the holes.

4. Appearance test refers to confirming that the end of the product received is free of oxidation, cracks, cracks, no defects on the surface of the porcelain body, no oxidation of the pads, the color difference of the product, and whether the texture is consistent.

Scope Of Application:According to the relevant testing standards, determine whether the MLCC is brand new, whether it is refurbished, whether the electrodes have traces of tin, oxidation, etc.

Morphological observation and measurement significance:

1、The microscopic geometry of the material surface affects many of its technical properties and functions to a large extent。

2、Observing the surface morphology of materials provides convenience for studying the morphological structure of samples, helps to monitor product quality and improve processes。

Application Field:Automotive, Communications, Consumer Electronics, Industrial, Healthcare and Military

Test Process:Material collection, record source and batch date, external observation of material by light microscope

Test Steps:Confirm the sample type → confirm the inspection specification → observe the sample → record the observed phenomenon → measurement data evaluation → result evaluation

Appearance Inspection Picture

Electrical Test

Capacitance (CP)--Test the capacitance value of the capacitor, and confirm whether the capacitor is qualified according to the nominal capacitance value and accuracy range of the capacitor.

Loss (DF)- -Judge the quality of the capacitor by testing the loss of the capacitor. If the loss is too high, it means that the quality of the capacitor is slightly poor.

Insulation Resistance (IR) --Test whether the resistance and leakage of the capacitor are within a reasonable range. If the resistance is too low, the leakage current will be too large, and the product will have quality risks.

Withstand Voltage (DCV)--Test whether the withstand voltage of the capacitor is within the range of the specification to confirm whether the capacitor can be used stably.

Electrical Performance Test Picture

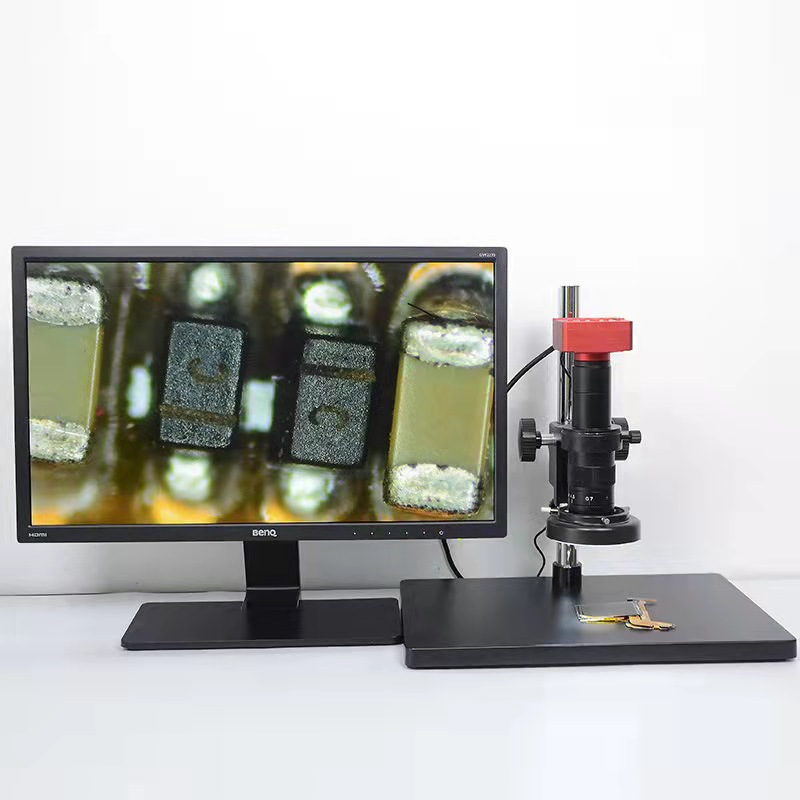

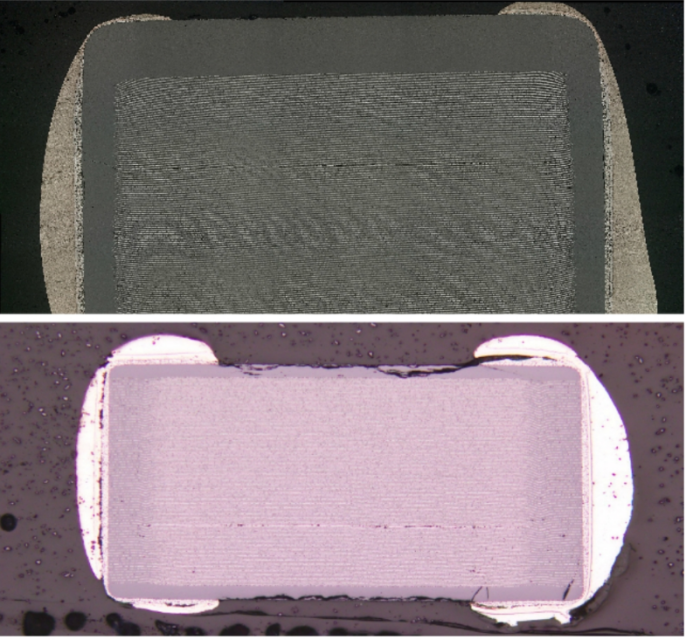

Slicing test

Description:Sectioning technique is the most commonly used sample preparation and analysis method to observe the cross-section structure of the sample.

Slice analysis technology is often used in PCB/PCBA, parts and other manufacturing industries, and is usually used for quality judgment and quality anomaly analysis, testing the quality of circuit boards, PCBA soldering quality testing, finding failure causes and solutions, and evaluating the process. Improvement, as the basis for objective inspection, research and judgment, is also one of the commonly used methods for MLCC failure analysis.

With the improvement of the refurbishment identification capabilities of various research institutes, the process of refurbishment manufacturers has gradually improved. At present, it is found that the refurbishment process is becoming more and more refined in the work, so the refurbishment identification requires long-term accumulation of identification experience. At the same time, the identification of refurbished devices has been able to control the entry of refurbished devices. At present, it is found that domestic packaging factories purchase wafers for packaging themselves or use wafers with similar functions for packaging, and mark the manufacturer and model of the corresponding brand. Purchasing such counterfeit components will bring great risks.

Slice Analysis:Slice analysis is to confirm the failure phenomenon of electronic components with the help of slice analysis technology and high magnification microscope, and analyze the defects of process and raw materials. Microsections prepared by microsectioning technology can be used for structural analysis of electronic components, inspection of the surface of electronic components and inspection of internal defects.

Slice Analysis Steps:Sampling → Cleaning → Vacuum Mounting → Grinding → Polishing → Micro-etching (if necessary) → Analysis (OM observation, SEM observation, EDS analysis, EBSD analysis, etc.)

Cross-section

Temperature Variation

Description:Melting, vaporization deformation, etc., so high temperature test is a very common test, which is used for the screening of components and the whole machine, reliability test, life test, accelerated life test, product material analysis and confirmation, and plays an important role in the verification of failure analysis. Function, we mainly use it as MLCC temperature coefficient for detection and confirmation.

Packaging and Logistics

Description:The final step of the testing service is packing and shipping. We attach no less importance to this link than other testing items. We recognize the importance of shipping components back to customers in a timely and safe manner. We provide complete packaging and shipping services to assist in You transport the goods to your designated destination.

Packaging And Logistics Pictures